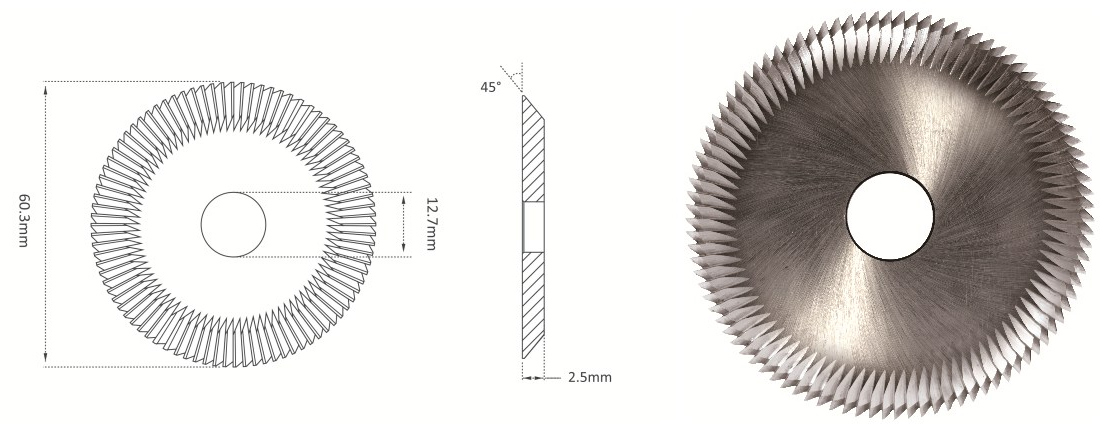

Angle Miling Cutter HJ-X23MC HSSCo-Coating φ60.3x2.5xφ12.7x45°

Product Description:

High Quality Best Price Angle Miling Cutter HJ-X23MC HSSCo-Coating φ60.3x2.5xφ12.7x45° , Accessories ,Cutter, Parts BUY NOW

Cutter From MK3 with Product Number: MK16995

This Weight Product: 80g

Specs:

Manufacturer: MK3

Condition: New

size: φ60.3x2.5xφ12.7x45°

Type: X23MC

Material : Carbide

Angle Miling Cutter HJ-X23MC HSSCo-Coating φ60.3x2.5xφ12.7x45° Features:

- Material: It is made of HSS-Co(HSSM35) material imported from Japan, high temperature quenching, hardness reaches HRC64-65, ultra-high temperature quenching, high hardness, copper key and iron key can all be cut, good wear resistance, Durable.

- Production process: Using full CNC grinding machine, full grinding technology, with sharper tip so as to cut the key easoer. The cut key is smooth and burr-free.

READ BEFORE USING :

1.Before running the machine, it is necessary to accurately adjust the cutter to ensure the key blank is matching with the mother key, and to avoid the tool being broken due to the unstable key assembly.

2.The cutter is clamped on the machine and the key blank and the mother key are fixed on the clamps. Do not clamp the key blank too tight. The patent key is close to the tracer and the key blank is close to the cutter. If the key blank is not fastened, the key blank should be removed and re-clamped.

3.When the machine is not running, clamp the cutter and cut from the left-to-right to check if the position of the parent key and the key blank are uniform. If not, re-clamp again.

4.After the machine is running, should wait the cutter is fully rotated before cutting.

5.When the key blank is close to the cutter, the clamp should be held to prevent the key blank from hitting the cutter after the cutter is fully rotated before cutting. So the first cutter tip which just touched the key blank won’t be damaged by uneven force.

6.When start to cut the key, it should slowly to push the clamp which fixed the key blank, so that the cutter tip won’t be damaged by uneven force.

Dimple Cutter V008 Carbide φ4x106°x33x4T Compatibility Key Cutting Machine:

Ilco 023, 025, 045; DL 143M,145, 145M, 148M; Taylor 143MT,145MT ,HPC 9160MC, 9180MC

Dimple Cutter V008 Carbide φ4x106°x33x4T Packaging Details: